|

Production introduction

The dry-type transformers are casted with epoxyresin,which are made of high quality materials by means of a strict process with advanced production and testing devices.The product features high reliability and long service life.In accordance with different operation environment,it can be equipped with different protection casings or without casing.It can replace the oil-immersed transformer and be used in the high buildings,business centers,airports,tunnels,chemical plants,nuclear power stations and watercrafts ect.

Normal service conditions

1)Altitude should not be over 1000m:indoor type

2)Highest ambient temperature should not over:+40oC;Highest daily average should not over temperature:+30oC

3)Highest annual average temperature should not over +20oC,lowest temperature should not below -5oC.We can provide transformer operated in special conditions according to user's requirement.

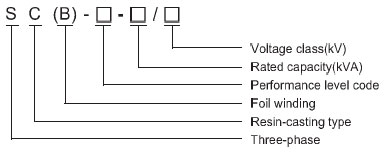

Model designation

Applicable standards

GB6450-1986 Dry-type power transformer

GB4208-1993 Casing protection grade(IP code)

GB/T10228-1997 Technical parameters and requirements for dry-type power transformer

Performance characteristics

1.The product is safe,fire-proof,pollution free,and can be used in the load center directly.

2.High mechanical strength,strong shour-circuit proof capacity,small partial discharge,excellent thermal stability,high reliability,and long service life.

3.Low loss,low noise,energy saving and maintenance free.

4.Excellent heat dissipation,great overload capacity and a large operating capacity is available when ONAF is applied.

5.Good humidity resistance,it's suitable for operating in the highly humid and harsh environment.

6.An intelligent signal and temperature control system is adopted,which can automatically monitor and display all working temperature of the three-phase windings.The blowing fan can give an alarm,switch on and off automatically and conduct tripping operation to protect the transformer.

7.Dur to the structure is compact and weight is light,it can save space and decrease the cost of installation.

Notes for placing orders

Transformer type:rated capacity kVA

Number of phases:three-phase single-phase

High voltage: KV/Low voltage:KV

Frequency:50HZ 60HZ

Tapping range:±4×2.5% ±3×2.5% other

Connection group:Yyn0 Dyn11 other

Impedance voltage:4% 6% other

Cooling method: ONAN ONAF

Protecting grade of outer casing:IP00 IP20 IP30 other

Method of incoming and outgoing line:

1.Incoming line to lower part and outgoing line from upper part

2.Incoming line to upper part and outgoing line form upper part

3.Incoming line to upper part and outgoing line form side part

4.other

*If customer has no requirement,the color of outer casing is light grey(the standard color of ANDELI),or you sould indicate color code that you want

Main technical parameters of SC(B)9-30~2500/10 series of transformers

| Rated capacity(KVA) | Voltage combination(KV) | Connecting groupid | No-load lossess(W) | Load-loss(W)(120oC) | Load-loss(W)(75oC) | Short circuit impedance(%) | No-load current(%) | Yawp grade(Db) | IP00(no crust) | IP20(IP23) | High voltage connection end(mm) | Low voltage connectionend(mm) | |||||||||

| High voltage(KV) | Tapping(%) | Low voltage(KV) | Length(mm) | Width(mm) | Height(mm) | Gauge(mm) | Gross weight(kg) | Length(mm) | Width(mm) | Height(mm) | Gross weight(kg) | ||||||||||

| 30 | 6 6.3 10 |

±5 ±2×2.5 |

0.4 | Yyn0 or Dyn11 | 210 | 745 | 650 | 4.0 | 2.8 | 45 | 670 | 500 | 700 | 400 | 280 | 1100 | 1000 | 1200 | 380 | M10 | 30×3 |

| 50 | 300 | 1050 | 915 | 2.5 | 45 | 720 | 500 | 770 | 400 | 400 | 1200 | 1000 | 1200 | 510 | M10 | 30×3 | |||||

| 80 | 410 | 1460 | 1275 | 2.4 | 46 | 760 | 500 | 950 | 400 | 500 | 1200 | 1000 | 1200 | 650 | M10 | 30×3 | |||||

| 100 | 450 | 1665 | 1455 | 2.2 | 46 | 980 | 600 | 1060 | 500 | 580 | 1300 | 1100 | 1400 | 820 | M10 | 30×3 | |||||

| 125 | 530 | 1950 | 1700 | 2 | 47 | 1030 | 650 | 1100 | 500 | 660 | 1300 | 1100 | 1400 | 880 | M10 | 30×3 | |||||

| 160 | 610 | 2250 | 1965 | 2 | 48 | 1050 | 650 | 1130 | 550 | 720 | 1500 | 1100 | 1400 | 940 | M10 | (a)40×4 | |||||

| 200 | 700 | 2670 | 2330 | 1.8 | 48 | 1100 | 650 | 1150 | 550 | 920 | 1500 | 1100 | 1600 | 1120 | M10 | (a)40×4 | |||||

| 250 | 810 | 2920 | 2550 | 1.8 | 49 | 1150 | 760 | 1200 | 660 | 1100 | 1500 | 1250 | 1600 | 1310 | M10 | (a)40×6 | |||||

| 315 | 990 | 3670 | 3205 | 1.6 | 49 | 1210 | 760 | 1250 | 660 | 1250 | 1500 | 1250 | 1600 | 1460 | M10 | (a)40×6 | |||||

| 400 | 1100 | 4220 | 3685 | 1.6 | 50 | 1270 | 760 | 1420 | 660 | 1600 | 1700 | 1250 | 1800 | 1850 | M10 | (b)60×6 | |||||

| 500 | 1300 | 5170 | 4515 | 1.6 | 51 | 1320 | 760 | 1500 | 660 | 1850 | 1700 | 1250 | 1800 | 2100 | M10 | (b)60×6 | |||||

| 630 | 1500 | 6220 | 5430 | 1.5 | 52 | 1360 | 760 | 1520 | 660 | 2200 | 1700 | 1250 | 1800 | 2450 | M10 | (c)80×8 | |||||

| 630 | 1460 | 6310 | 5510 | 6 | 1.5 | 52 | 1430 | 760 | 1360 | 660 | 2100 | 1700 | 1250 | 1800 | 2350 | M10 | (c)80×8 | ||||

| 800 | 1710 | 7360 | 6425 | 1.5 | 53 | 1470 | 1000 | 1460 | 820 | 2300 | 1900 | 1500 | 1800 | 3000 | M10 | (c)80×8 | |||||

| 1000 | 1990 | 8600 | 7510 | 1.3 | 54 | 1540 | 1000 | 1560 | 820 | 2800 | 1900 | 1500 | 1800 | 3100 | M10 | (d)100×10 | |||||

| 1250 | 2350 | 10260 | 8955 | 1.3 | 55 | 1610 | 1000 | 1620 | 820 | 3200 | 1900 | 1500 | 2000 | 3510 | M10 | (d)100×10 | |||||

| 1600 | 2750 | 12420 | 10840 | 1.3 | 56 | 1710 | 1250 | 1700 | 1070 | 3800 | 2100 | 1800 | 2000 | 4150 | M10 | (d)120×10 | |||||

| 2000 | 3735 | 15300 | 13355 | 1.1 | 56 | 1830 | 1250 | 1930 | 1070 | 4800 | 2100 | 1800 | 2200 | 5180 | M16 | (e)120×12 | |||||

| 2500 | 4500 | 18180 | 15870 | 1.1 | 57 | 1850 | 1250 | 1970 | 1070 | 5400 | 2100 | 1800 | 2300 | 5800 | M16 | (e)120×15 | |||||

Main technical parameters of SC(B)10-30~2500/10 series of transformers

| Rated capacity(KVA) | Voltage combination(KV) | Connecting groupid | No-load lossess(W) | Load-loss(W)(120oC) | Load-loss(W)(75oC) | Short circuit impedance(%) | No-load current(% | Yawp grade(Db) | IP00(no crust) | IP20(IP23) | High voltage connection end(mm) | Low voltage connection end(mm) | |||||||||

| High voltage(KV) | Tapping(%) | Low voltage(KV) | Length(mm) | Width(mm) | Height(mm) | Gauge(mm) | Gross weight(kg) | Length(mm) | Width(mm) | Height(mm) | Gross weight(kg) | ||||||||||

| 30 | 6 6.3 10 |

±5 ±2×2.5 |

0.4 | Yyn0 or Dyn11 | 190 | 700 | 610 | 0.4 | 2.6 | 44 | 670 | 500 | 700 | 400 | 280 | 1100 | 1000 | 1200 | 380 | M10 | 30×3 |

| 50 | 270 | 990 | 865 | 2.2 | 44 | 720 | 500 | 770 | 400 | 400 | 1200 | 1000 | 1200 | 510 | M10 | 30×3 | |||||

| 80 | 360 | 1380 | 1205 | 2.0 | 45 | 760 | 500 | 950 | 400 | 500 | 1200 | 1000 | 1200 | 650 | M10 | 30×3 | |||||

| 100 | 400 | 1570 | 1370 | 2.0 | 45 | 980 | 600 | 1060 | 500 | 580 | 1300 | 1100 | 1400 | 820 | M10 | (a)30×3 | |||||

| 125 | 480 | 1840 | 1605 | 1.8 | 46 | 1030 | 650 | 1100 | 500 | 660 | 1300 | 1100 | 1400 | 880 | M10 | (a)30×3 | |||||

| 160 | 540 | 2130 | 1860 | 1.8 | 47 | 1050 | 650 | 1130 | 550 | 720 | 1500 | 1100 | 1400 | 940 | M10 | (a)40×4 | |||||

| 200 | 620 | 2530 | 2210 | 1.6 | 47 | 1100 | 650 | 1150 | 550 | 920 | 1500 | 1100 | 1600 | 1120 | M10 | (a)40×4 | |||||

| 250 | 720 | 2750 | 2400 | 1.6 | 48 | 1150 | 760 | 1200 | 660 | 1100 | 1500 | 1250 | 1600 | 1310 | M10 | (a)40×6 | |||||

| 315 | 880 | 3470 | 3030 | 1.4 | 48 | 1210 | 760 | 1250 | 660 | 1250 | 1500 | 1250 | 1600 | 1460 | M10 | (a)40×6 | |||||

| 400 | 970 | 3990 | 3485 | 1.4 | 49 | 1270 | 760 | 1420 | 660 | 1600 | 1700 | 1250 | 1800 | 1850 | M10 | (b)60×6 | |||||

| 500 | 1160 | 4880 | 4260 | 1.4 | 50 | 1320 | 760 | 1500 | 660 | 1820 | 1700 | 1250 | 1800 | 2100 | M10 | (b)60×6 | |||||

| 630 | 1340 | 5870 | 5125 | 1.3 | 51 | 1360 | 760 | 1520 | 660 | 2200 | 1700 | 1250 | 1800 | 2450 | M10 | (c)80×8 | |||||

| 630 | 1290 | 5960 | 5200 | 6 | 1.3 | 51 | 1430 | 760 | 1360 | 660 | 2100 | 1700 | 1250 | 1800 | 2350 | M10 | (c)80×8 | ||||

| 800 | 1520 | 6950 | 6070 | 1.3 | 52 | 1470 | 1000 | 1460 | 820 | 2300 | 1900 | 1500 | 1800 | 3000 | M10 | (c)80×8 | |||||

| 1000 | 1760 | 8130 | 7095 | 1.1 | 53 | 1540 | 1000 | 1560 | 820 | 2800 | 1900 | 1500 | 1800 | 3100 | M10 | (d)100×10 | |||||

| 1250 | 2080 | 9690 | 8460 | 1.1 | 54 | 1610 | 1000 | 1620 | 820 | 3200 | 1900 | 1500 | 2000 | 3510 | M10 | (d)100×10 | |||||

| 1600 | 2440 | 11730 | 10240 | 1.1 | 55 | 1710 | 1250 | 1700 | 1070 | 3800 | 2100 | 1800 | 2000 | 4150 | M10 | (d)120×10 | |||||

| 2000 | 3320 | 14450 | 12615 | 1.0 | 55 | 1830 | 1250 | 1930 | 1070 | 4800 | 2100 | 1800 | 2200 | 5180 | M16 | (e)120×12 | |||||

| 2500 | 4000 | 17170 | 14990 | 1.0 | 56 | 1850 | 1250 | 1970 | 1070 | 5400 | 2100 | 1800 | 2300 | 5800 | M16 | (e)120×15 | |||||

Chinese

Chinese Russian

Russian German

German Spanish

Spanish French

French Italian

Italian Portuguese

Portuguese Japanese

Japanese Indonesian

Indonesian Vietnamese

Vietnamese

Add to Inquiry Basket

Add to Inquiry Basket View Inquiry Basket

View Inquiry Basket The products that you selected had been put into inquiry basket !

The products that you selected had been put into inquiry basket !